Boosting Industrial Efficiency

IoT and IoE with Microsoft Architecture

The Internet of Things (IoT) is a network of physical objects ("things") equipped with sensors, software, and other technologies to connect and exchange data with other devices and systems over the Internet. These objects can include smart home devices, vehicles, industrial machines, and more. IoT aims to improve the efficiency, monitoring, and management of various processes by collecting and analyzing real-time data.

Internet of Everything (IoE):

The Internet of Everything (IoE) expands on IoT by connecting physical things, people, processes, and data. IoE integrates advanced technologies to create more integrated systems capable of intelligent communication and collaboration. It includes four main components:

1. People - Connecting individuals and systems.

2. Data - Analyzing data collected from connected objects.

3. Processes - Optimizing business and operational processes.

4. Things—the connected objects themselves.

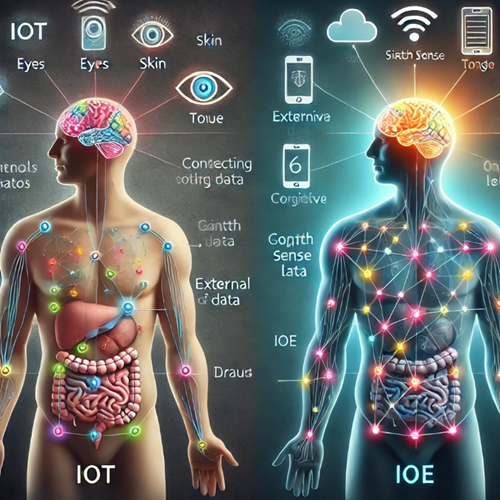

The illustration compares IoT and IoE using the human body analogy. On the left, it depicts IoT with sensors connected to the brain, while on the right, it illustrates IoE with additional external connections and a cognitive layer for enhanced performance.

Implementing IoT and IoE in industrial machines should focus on improving efficiency, reducing failures, and enabling preventive maintenance. Here are examples and methods for implementation: 1. Connecting Sensors to Machines: Install machine sensors to collect data such as temperature, pressure, vibrations, etc. - Use intelligent technologies to analyze real-time data and identify issues before they occur. 2. Remote Management: Connect machines to the cloud for remote control and management. - Cloud-based management systems and software are utilized to monitor processes and maintenance. 3. Preventive Maintenance: Employ preventive maintenance models. Implementing IoT and IoE industrial machines. s Implementing IoT and IoE in industrial machines should focus on improving efficiency, reducing failures, and enabling preventive maintenance. Here are examples and methods for implementation: 1. Connecting Sensors to Machines: - Install machine sensors to collect data like temperature, pressure, vibrations, etc. - Use intelligent technologies to analyze real-time data to identify issues before they occur. 2. Remote Management: Connect machines to the cloud for remote control and management. - Cloud-based management systems and software are used to monitor processes and maintenance. 3. Preventive Maintenance: - Use preventive maintenance models by analyzing machine data. - Identify abnormal patterns and alert potential issues before they cause downtime. 4. Process Improvement: - Automate processes by integrating IoT into production systems. - Use IoE to link employees, processes, and machines optimally. 5. Data Sharing and Analysis: Share data between systems for integrated analysis. - Use tools like Microsoft Azure, which offers advanced analytics, artificial intelligence, and automation capabilities. Practical Example: Implementing Microsoft Architecture in Industrial Machines. According to the provided presentation, here is how Microsoft's architecture can be applied in this field: - Microsoft Azure: Microsoft's cloud platform enables the collection and analysis of machine data in the cloud, improving preventive maintenance and providing real-time insights. AI Bots & Agents: Use AI-based bots and agents to automate processes and answer common operator questions. Office 365 and Teams are tools for direct and efficient communication between operators and machines, including document management and chat functions. - Log Analytics: Analyzing logs to identify issues and faults in real-time, improving operational activity. By integrating these technologies, an innovative and integrated system can be created to enhance the operational efficiency of industrial machines, reduce faults, and improve overall performance.